- Home

- About CTI

- Our Services

- Investor Relations

- CTI Mall

- Resource Center

- Reports Validation

- Join Us

-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in CTI’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. CTI is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

- Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

QUALITY & VALUE

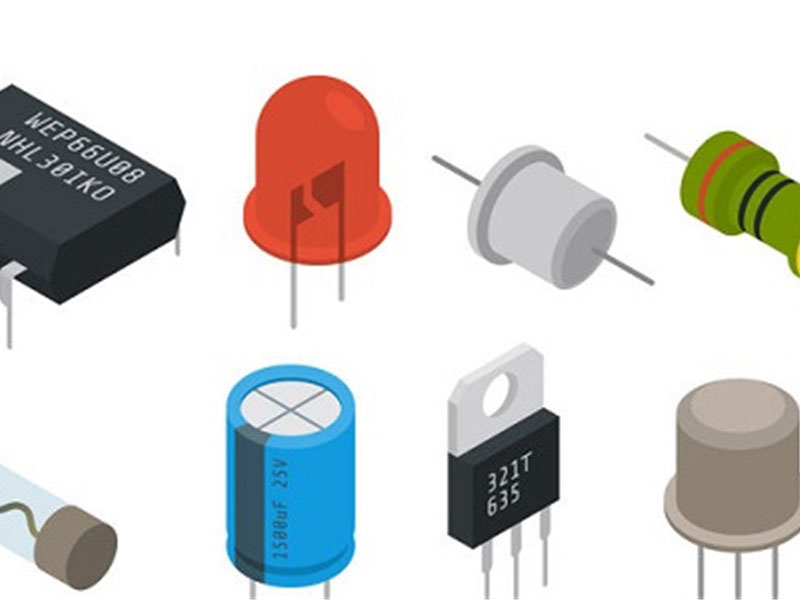

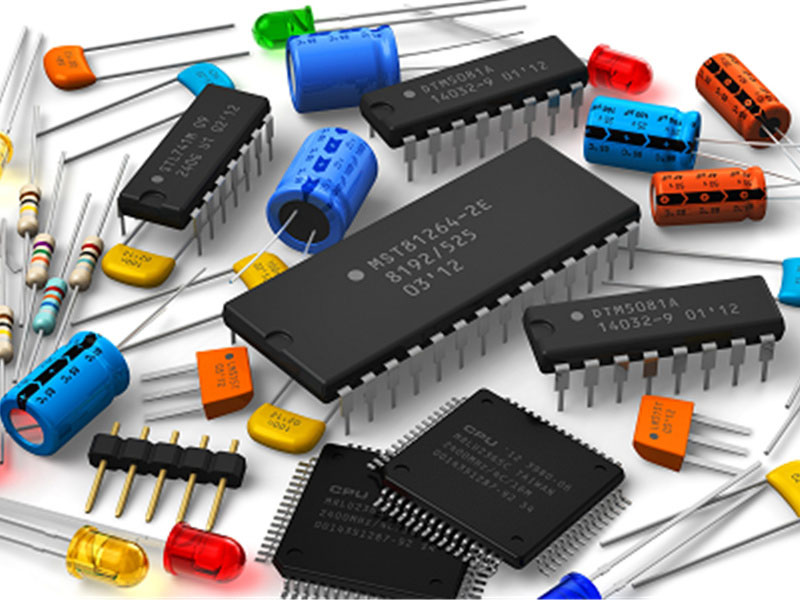

The one main reason for the early failure of electronic products is the improper use of electronic soldering materials or the quality of the soldering materials product. CTI can make the quality and reliability evaluation for solder paste, solder bar, solder wire, flux, cleaning agent and other soldering materials. These can help to improve the quality of products, optimize the processing and mounting process and ensure the reliability of products.

- Consulting quotation

- Online shopping mall

◉ Business Challenges

What are the potential quality hazards of IC SMT process?

How is the reliability of SMT process verified?

◉ Service Content

Ⅰ. Applicable Test Standards

J-STD-004B Requirements for Soldering Fluxes

J-STD-005 Requirements for Soldering Pastes

J-STD-006 Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications

JIS Z 3197 Testing methods for soldering fluxes

JIS Z 3283 Resin flux cored solders

ASTM D1298 Standard Test Method for Density,Relative Density,or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

GB/T 507 Insulating liquids. Determination of the breakdown voltage at power frequency

GB/T 6324.2 Test method of organic chemical products. Part 2:Determination of dry residue after evaporation on a water bath for volatile organic liquids

GB/T 9491 Liquid flux for soldering(Rosin base)

GB/T 9740 Chemical reagent. General method for the determination of dry residue after evaporation

GB/T 12582 Liquid hydrocarbons. Determination of electrical conductivity. Precision meter

IPC TM-650 Test Methods Manual, etc.

Ⅱ. Product Range

Electronic and electrical products, Solder paste, Solder, Solder wire, Flux, Cleaning agent, etc.

Ⅲ. Standard Sample Requirements

Please contact our business or customer service, based on specific standards.

Ⅳ. Test Item

|

Main Test Items |

|

|

Specific gravity/Density |

Wetting Test |

|

Solids Content |

Solder Paste Metal Content by Weight |

|

Spread Test |

Flux Content by Weight |

|

Quantitative Halide Content Tests |

Copper plate corrosion Test |

|

Resistivity test of aqueous solution |

Determination of dry residue after evaporation |

|

Cross-section analysis |

Electrical conductivity |

|

Dryness |

Breakdown voltage |

|

Acid Value Determination |

Withstand voltage |

|

Copper Mirror Test |

Physical stability |

|

Surface Insulation Resistance Test |

Uniformity |

|

Electrochemical Migration (ECM) Test |

Appearance and dimensions |

◉ CTI Solution

CTI provides a comprehensive one-stop solution of reliability testing, including:

Environmental test

Reliability test

Reliability design

Reliability analysis

Product evaluation

Reliability training and consulting

◉ Our Strengths

CTI has many advanced equipments and has passed CMA/CNAS qualification accreditation, the test data is accurate and reliable, and the test report has international credibility.

The scientific laboratory information management system ensures the efficient operation of each service link.

The technical expert team has rich practical experience and can provide professional, rapid and comprehensive one-stop service.

The service network is all over the world, and many first-line brands designate cooperative laboratories.

◉ Service Process

Consult customer service → confirm the test plan → fill in the application form → send the sample → pay the test fee → test → send electronic report → express paper report

◉ Frequently Asked Question

How long does the test period take?

The normal period is 5-7 working days (except the time when the sample is in the test chamber). If you need urgent help, please contact our sales or customer service.

How much sample is needed for SIR (surface insulation resistance) and ECM (electrochemical migration)test of flux?

It is each recommended to send 200ml flux for SIR or ECM test.

what is the channel definition in ECM test?

In the process of ECM testing or SIR testing, To determine the number of test channels is to determine the number of positions of insulation resistance monitoring.

How long is the corrosion test exposure period of solder paste?

Different standards provide different test time. For example, GB/T 9491 recommends 7 or 14 days, while IPC J-STD-004B recommends 10 days, so the test time should be based on the standard specified by the customer.

How much solder paste sample is needed to test the wettability test?

It is recommended to send samples for more than 400g. If other test items need to be tested at the same time, it is advised to send more samples for standby use.

- About CTI

- Our Services

- Investor Relations

- CTI Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- CTI Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号